WD Module

for diffusion dialysis

Introducion

The WD membrane spiral module enables the highest recovery rates for acids and bases from solutions in diffusion dialysis processes, e.g., with metal salts.

ADVANTAGES OF WD-MODULE IN SURFACE TECHNOLOGY APPLICATIONS

Our WD Membrane Spiral Modules can be used in a broad range of applications. Industries in which our modules can be used for acid or base recovery include the surface treatment industry, the printed circuit board industry, the semiconductor industry, the recycling of fly ashes, hydrometallurgy, etc.

ACIDS

METALS

BASES

ADVANTAGES OF WD-MODULE IN SURFACE TECHNOLOGY APPLICATIONS

The WD Membrane Spiral Module excels in achieving the highest recovery rates.

For instance, in an anodizing process, it can recover up to 95 % of the free acid from the purge stream, with less than 1 % of the aluminum returning to the process along with the recovered acid. In the case of base recovery processes, our WD Membrane Spiral Module attains an impressive 70% recovery of the free base.

The recovery of acids or bases using our WD Membrane Spiral Modules can also be utilized for metal recovery processes. Please feel free to contact us to assess your application, including special cases

The continuous operation of diffusion dialysis allows core processes, e.g., in surface treatment, to operate steadily at the optimum operating point, resulting in minimal material losses and the highest product quality.

Subsequent waste management also becomes more cost-effective due to diffusion dialysis with WD Membrane Spiral Modules. Environmental guidelines can be complied with reduced operating costs.

Additionally, the replacement of membrane spiral modules leads to very low costs compared to conventional plate and frame membrane devices for diffusion dialysis.

WD Membrane Spiral Module enables nearly complete recovery of free acids and bases. These recovered raw materials can be further utilized at the highest value level and reduce the salt load in wastewater.

With its high-volume density of the membrane surface, the WD Membrane Spiral Module can process considerably more solution than conventional devices within the same space requirement. This design also enables high process availability and minimizes maintenance time. The modules are easily scalable according to your requirement.

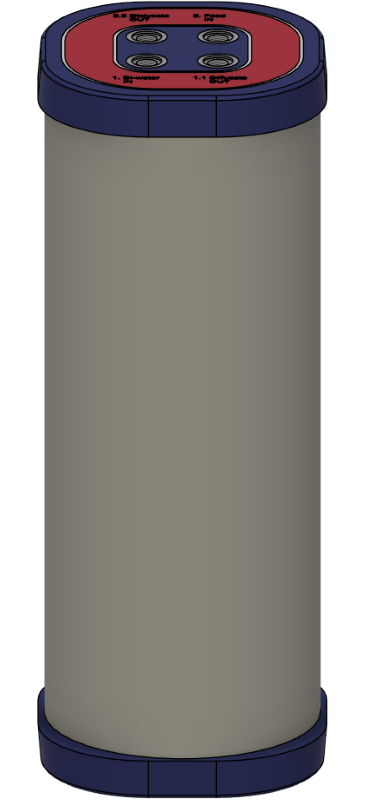

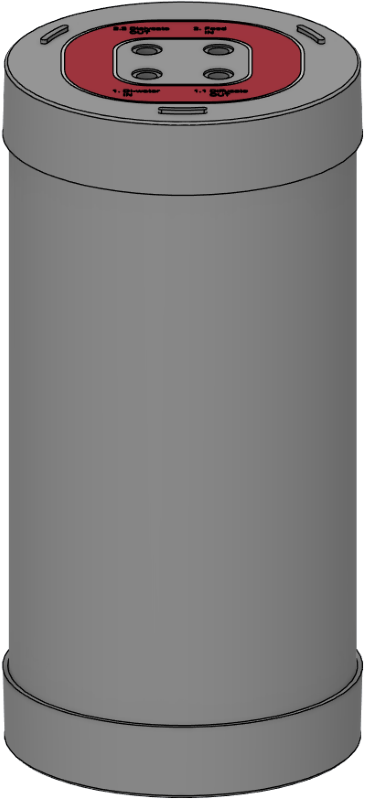

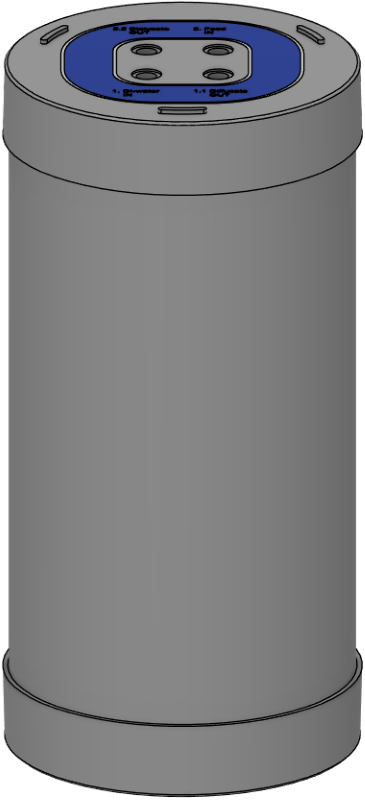

VERSIONS OF WD MODULE

WD-AR10

WD-AR20

WD-BR20

We offer different models of our WD Membrane Spiral Module to meet specific requirements.

Two Distinct Perfomance Sizes:Choose between WD10, offering a flow rate of 5-15 l/h, and WD20, designed for a flow rate of 10-30 l/h.

Customized Membranes: Based on your specific application, we select the most suitable membrane to maximize your benefit.

End sealing: For highly aggressive solutions, the WD Spiral Membrane Module can be supplied with a highly resistant potting.

Please refer to our data sheets for specifications of different versions:

Please feel free to contact us in order to find out the suitable membrane spiral module for your application (also special applications).

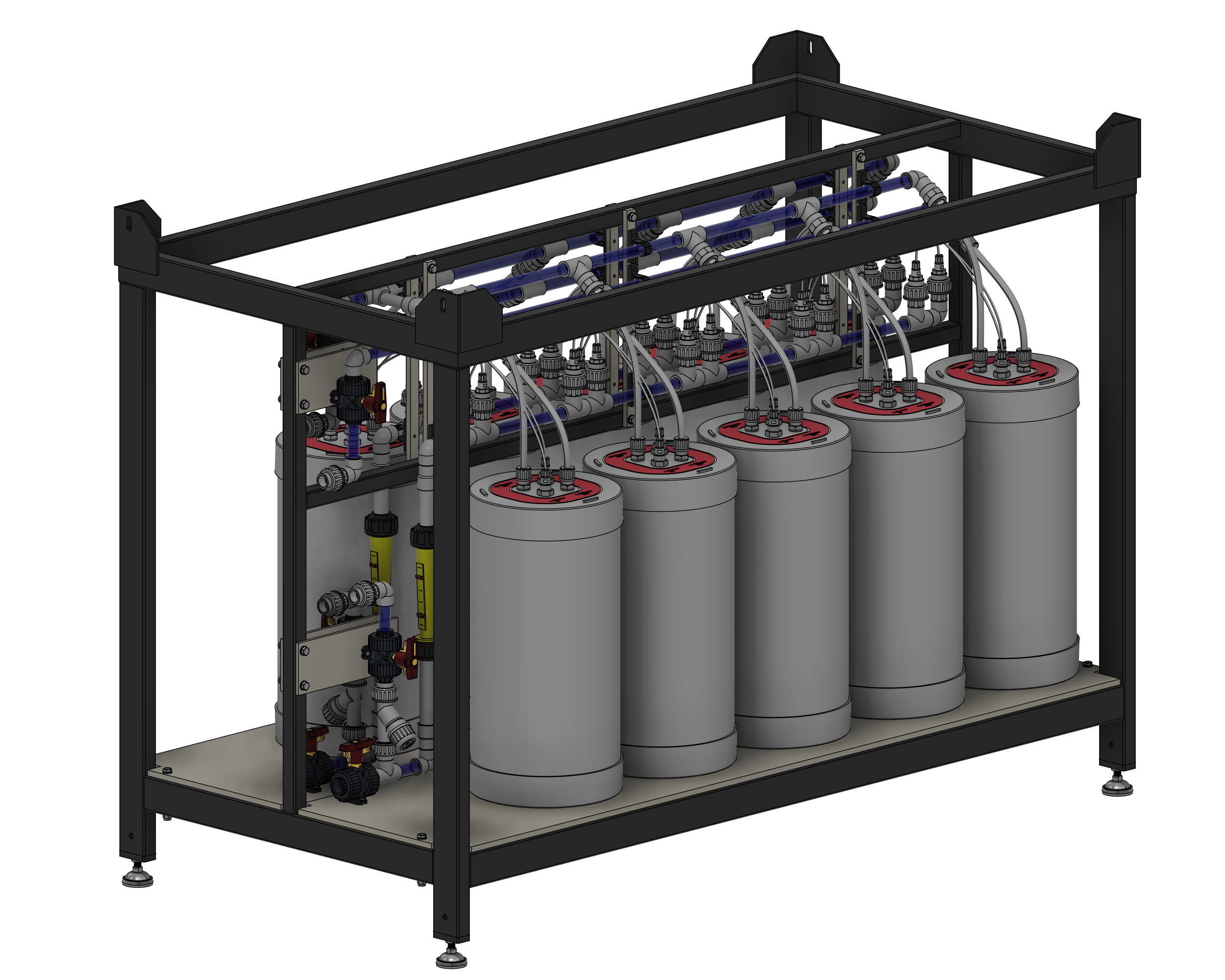

Pre-assembled module boxes and other equipment

In addition to the delivery of WD Membrane Spiral Modules, we also offer stackable module boxes and systems equipped with up to 10 WD modules for end customers and plant manufacturers.

- The DS10-10 module system can be equipped with up to 10 WD10 series Membrane Spiral Modules.

Technical data:

- Dimensions: 1200 x 800 x 1200 mm (L x W x H)

- Modules: up to 10 modules of the WD10 series

- Flow rate: 90-150 l/h (10 modules)

- Weight: approx. 200 kg (incl. modules, without liquids)

Advantages:

- Very compact

- Stackable

- Complete housing made of PP

- Ready for plug and operate

Description:

- The DS20-20 module system can be equipped with up to 10 WD20 series Membrane Spiral Modules.

Technical data:

- Dimensions: 1600 x 800 x 1200 mm (L x W x H)

- Modules: up to 10 modules of the WD20 series

- Flow rate: 90-300 l/h (10 modules)

- Weight: approx. 285 kg (incl. empty modules)

Advantages:

- Very compact

- Stackable

- Cost-effective

- Ready for plug and operate

Furthermore, there is the option to order a system that perfectly suits your needs. In addition to tailored solutions, we presently provide the following standardized variants:

Description:

- The fully automatic supply unit of the DDSU150 series is suitable for operating up to three module systems of the DS10 series or one module system of the DS20 series.

Technical data:

- Dimensions: 1200 x 800 x 1200 mm (L x W x H)

- Pump capacity: max. 200 l/h

- Power supply: L1/N/PE AC 230 V 50 Hz

- Operating pressure: max. 4.0 bar

- Storage tanks: approx. 65 l per tank

- Empty weight: approx. 220 kg

Advantages:

- Integrated storage tanks

- Optional safety filtration

- Stackable with modular system DS10-10

- Complete housing made of PP-H

Description:

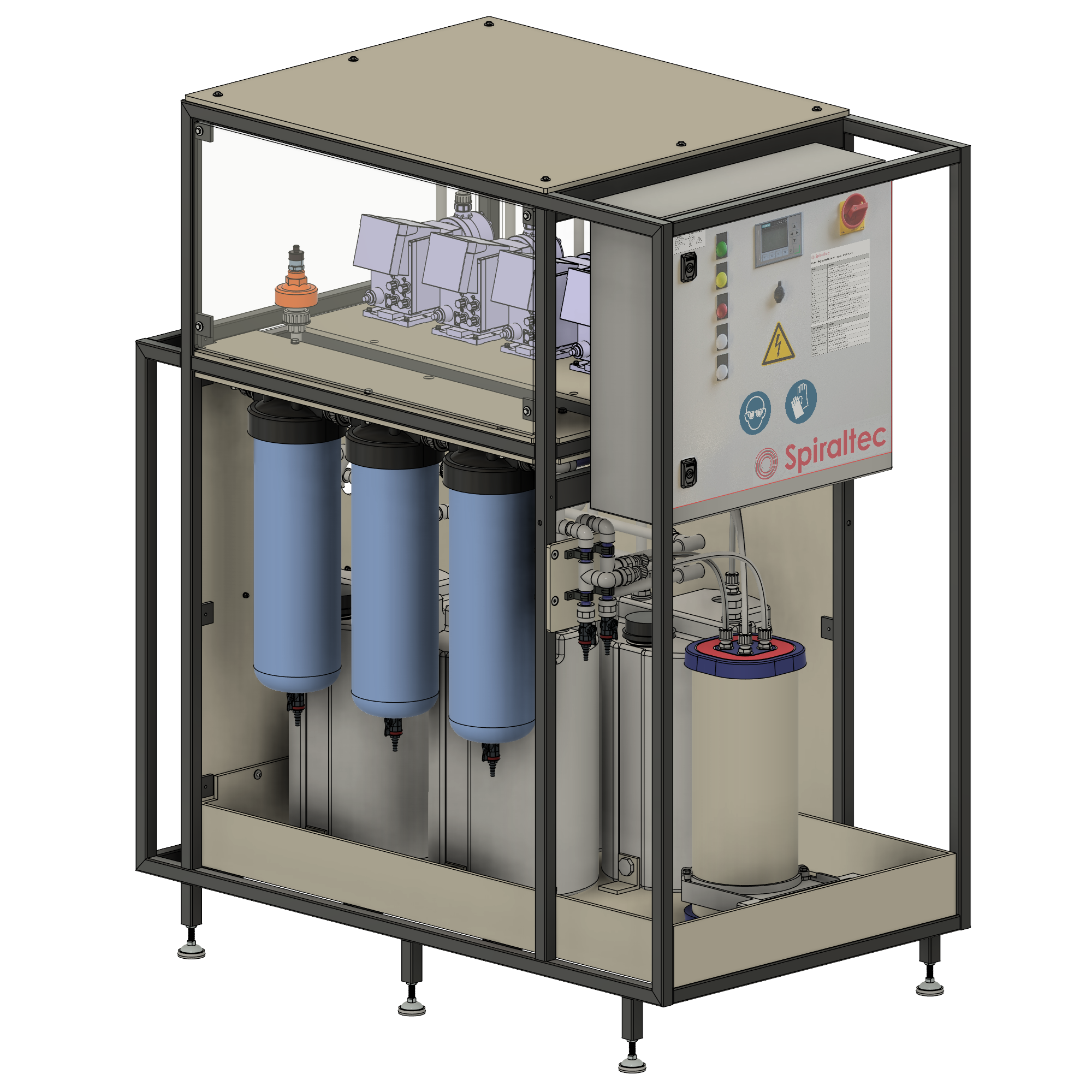

- Fully automatic compact system for small applications. It can be equipped with any Membrane Spiral Module.

Technical data:

- Dimensions: 1400 x 820 x 1700 mm (L x W x H)

- Pump capacity: max. 25 l/h

- Power supply: L1/N/PE AC 230 V 50 Hz

- Operating pressure: max. 2.5 bar

- Storage tanks: 35 l per tank

- Empty weight: approx. 250 kg

Advantages:

- Integrated storage tanks

- Integrated safety filtration

- Flexible adjustable volume flows

Description:

- Fully automatic compact system for smaller applications. It is equipped with any two Membrane Spiral Modules.

Technical data:

- Dimensions: 1400 x 820 x 1700 mm (L x W x H)

- Pump capacity: max. 60 l/h

- Power supply: L1/N/PE AC 230 V 50 Hz

- Operating pressure: max. 2.5 bar

- Storage tanks: 35 l per tank

- Empty weight: approx. 275 kg

Advantages:

- Integrated storage tanks

- Integrated safety filtration

- Flexible adjustable volume flows

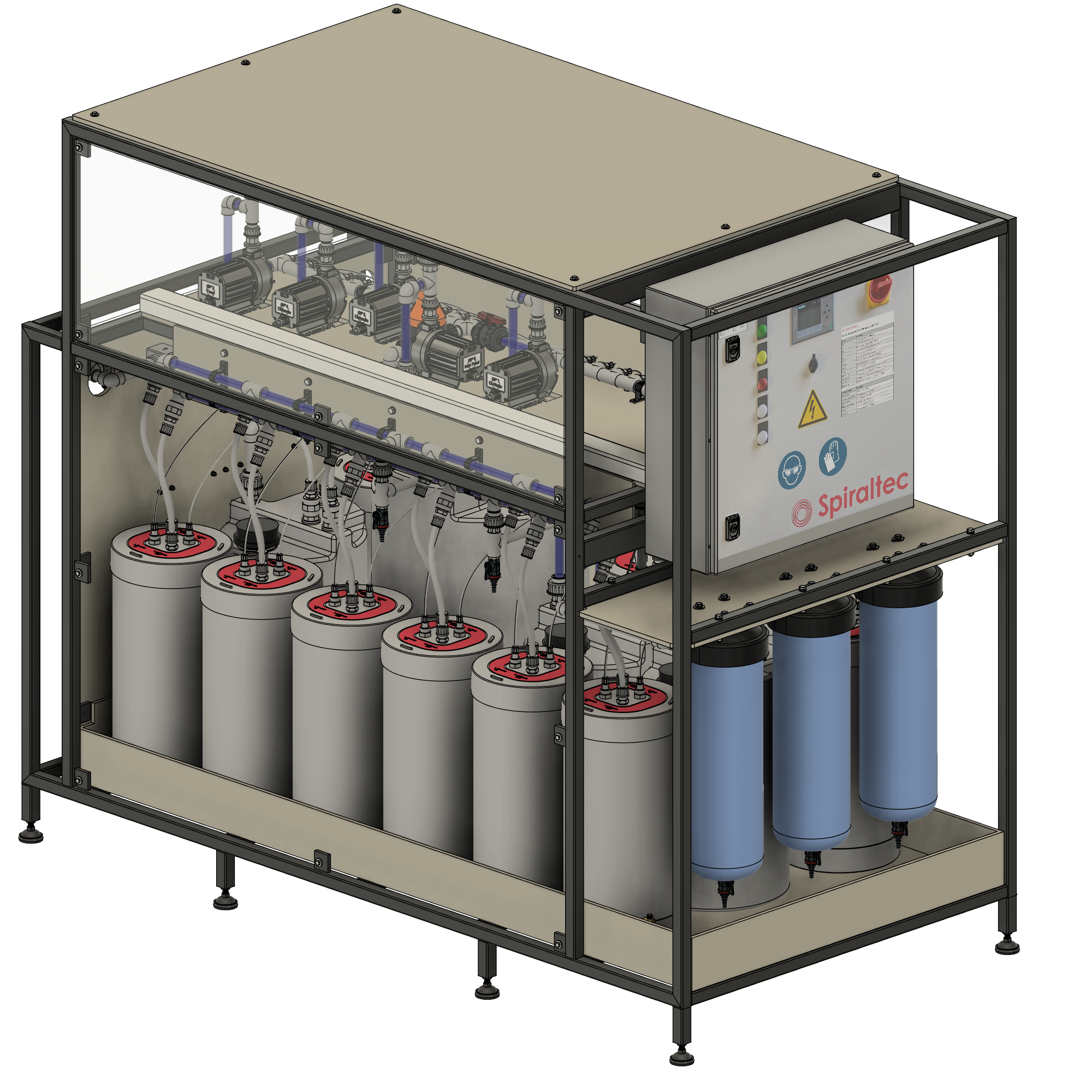

Description:

- Fully automatic compact system for medium-sized applications. It is equipped with any four Membrane Spiral Modules.

Technical data:

- Dimensions: 1600 x 820 x 1700 mm (L x W x H)

- Pump capacity: max. 120 l/h

- Power supply: L1/N/PE AC 230 V 50 Hz

- Operating pressure: max. 2.5 bar

- Storage tanks: 35 l per tank

- Empty weight: approx. 300 kg

Advantages:

- Integrated storage tanks

- Integrated safety filtration

- Flexible adjustable volume flows

Description:

- Automatic compact unit for mid-range applications. It is equipped with any eleven Membrane Spiral Modules.

Technical data:

- Dimensions: 1970 x 1000 x 1650 mm (L x W x H)

- Pump capacity: max. 220 l/h

- Power supply: L1/N/PE AC 230 V 50 Hz

- Operating pressure: max. 2.5 bar

- Storage tanks: 3x35 l; 1x100 l

- Empty weight: approx. 440 kg

Advantages:

- Integrated storage tanks

- Integrated safety filtration

- Flexible adjustable volume flows

We will be glad to help you!

Ongoing research for new areas of application.